Project Description

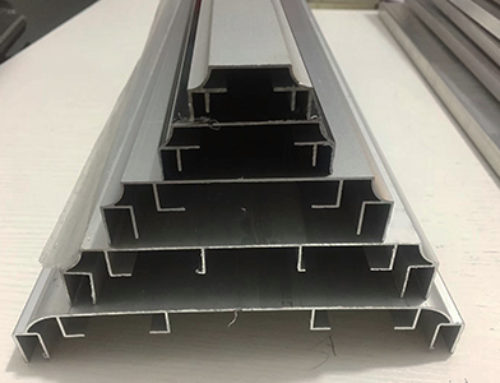

Extruded Aluminium Motor Enclosure, also known as Aluminium Extrusion Motor housing, Aluminium Motor Casing:

Because Aluminum has the good performance of extensibility and lowers specific gravity, the motor housing made of aluminium alloy has advantages in lightweight, high strength, large cooling area, good heat dissipation, great thermal conductivity, tensile strength, surface appearance, etc. It is widely used in the generator, starting motor, micro motor, and other parts.

With the energy conservation and emission reduction and the concept of low-carbon deeply popular, the new energy automobile industry is also experiencing a boom in research & development and volume production. The aluminium alloy water cooling cycle heat dissipation housing is widely used as the supporting products of new energy vehicles.

What is aluminium extrusion water cooling cycle heat dissipation housing?

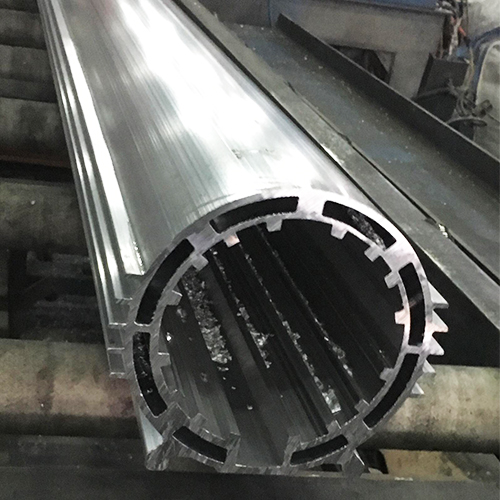

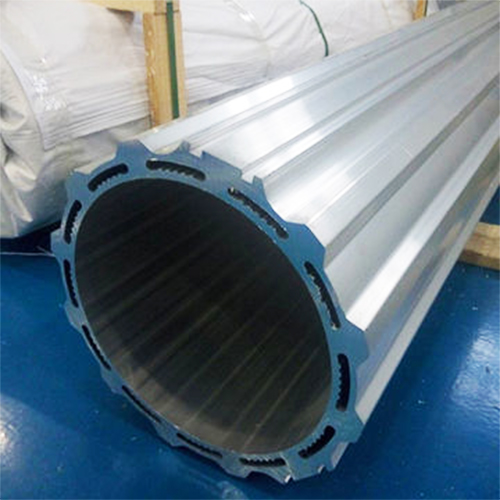

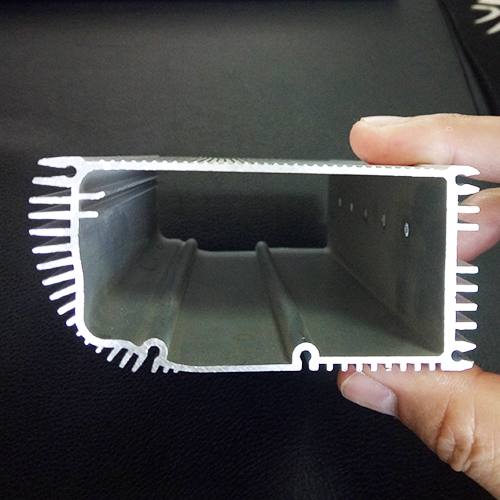

Aluminium water-cooled motor housing is extruded. And the cooling water circulation in the inner lining of the shell is carried out. Taking away the heat generated by the motor run time. This process makes the motor housing almost no heat dissipation outside. The water cycle replaces the cooling fan.

The research and development of aluminium extruded motor housing have successfully replaced the motor housing in aluminium die-cast forming. These problems that motor housing in aluminium die casting faced that poor density of materials, easy to cause porosity, blowholes and other casting defects will be solved and successfully avoid the defects of poor surface casting roughness and lower corrosion resistance.

Application:

Hoonly Aluminum Extruded Motor Housing ( or Extruded Aluminium Motor Enclosure) has a better performance than other materials: Lightweight; Low noise; Energy saving and high efficiency, using aluminium alloy 6063 as the material is extruded by hot extrusion. Inner hole concentricity ≤0.07 mm.

Aluminium extruded motor housing is mainly applied to the micromotor, environmental air conditioner motor, Water cooled air conditioning motor, air compressor motor, negative pressure blowers, electric motor, electro-tricycle motor, cooling tower machine, electric power tool motor, and gear motor etc.

Learn more about extruded aluminium motor housing, please visit our blog: Overview Extruded Aluminium Motor Body