Project Description

Aluminium Grille

Aluminium grille is one material of suspended ceiling, it is featured in open vision, ventilation, air permeability, the neat

lines and lively, distinct gradations, simple and convenient of installation or disassembly. It has become one of the popular

product in decoration market. Aluminium grille can be mainly divided into Groove Aluminum Grille and Flat Aluminum

Grille.

Specifications:

Conventional aluminium grille (Veneered side) standard: 10 mm or 15 mm, Available Width: 20 mm, 40 mm, 60 mm, and 80 mm.

Grille size: 5050 mm, 75×75 mm, 100×100 mm, 125×125 mm, 150×150 mm, 200×200 mm

Flake Grille size: 10×10 mm, 15×15 mm, 25×25 mm, 30×30 mm, 40×40 mm, 50×50 mm, 60×60 mm.

The smaller spacing, the higher price.

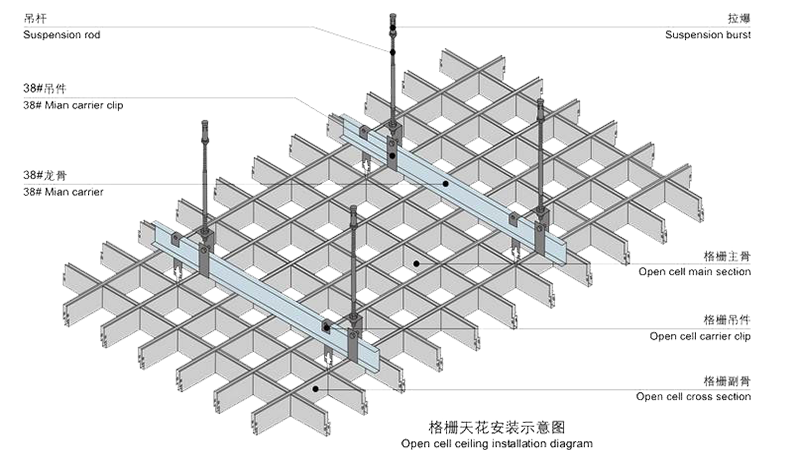

Construction Technology:

1. Fix height dimension, then mark horizontal line used ink fountain on the wall.

2. Fix hanging steel bars using expansion bolt, then fasten the ceiling light steel keel below the bars, remains the steel keel

level.

3. Nail aluminium horn line along the horizontal well with masonry nail.

4. Assembling aluminium grille well.

5. Put the assembled aluminium grille on the aluminium angle, in the middle of the position with a wire directly on the light

steel keel.

Aluminium Grille Installation Instruction

(1). Snap the line

Mark the level points using balance level on each wall or pillar, (if the wall is longer, much more points should be labeled

in the middle), pop-up level line (level line above the ground shall generally be 500 mm), from level line to ceiling height

of design, pop-up level line in chalk color along with the wall or pillar, that is underline of suspended ceiling. At the same

time, according to the designed plane graph, pop-up the location of the key keel on the concrete roof. The key keel should be

divided from ceiling centre to points on both sides, the maximum interval is 1000 mm, and the fixed point spacing of hanger rod

is 900 mm~1000 mm. If meet the case that the fixed points of beam & pipe are greater than the designed and code requirements

just increase the number of fixed points.

(2). Fixed Hanging Rods

Adopting the expansion bolt to fix hanging rods. ф 6mm hanging rod is available. The rod material is cold drawn steel bar

or wire rod steel, but use round bar should adopt mechanical to straighten. One end of the rod should weld with L30 * 30 * 3

angle, (Angle aperture should be determined according to the hanging rod and the diameter of the bolts), the other end

should be tapped more than 100 mm screw, also can buy finished screw welding. Well-done hanging rods should do antirust

processing, they are fixed on the roof with expansion bolt. (Using the impact hammer drilling, the aperture should be slightly

greater than the diameter of the bolts.)

(3). Light Steel Keel Installing

Light steel keel should be hanging on the rods (If the suspended ceiling is lower, this procedure can be omitted, directly

under the procedure). Generally using 38 light steel keel, the span is 900 mm ~ 1000 mm. Light steel keel should be

installed parallel to the room, and be arch camber at the same time, the bulging height span is 1/200 ~ 1/300 of the

room. Light steel keel cantilever section should not be more than 300 mm, otherwise, it should add more rods. Extension of

the main keel should be butted, adjacent keel butted joints should be staggered each other. After hang up the light steel

keel, the structure should be the basic level.

If the span is greater than 15 meters, there should add a big keel every 15 meters in the main keel, and more the big

keel should be welded solidly perpendicular to the main keel.

(4). Spring leaf installation

Finishing the connection between hanging rods and light steel keel, the span is 900 mm ~ 1000 mm, then loading the spring

leaf on the hanging rod.

(5). Aluminium Grille installation

Hoisting the pre-assembled aluminium grille with a hook thread to the main keel, when connecting the whole grilles, adjust to

the level.