Project Description

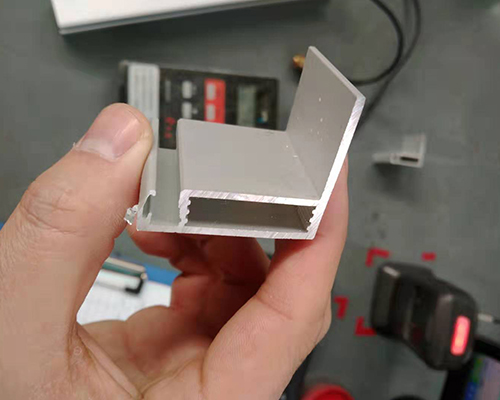

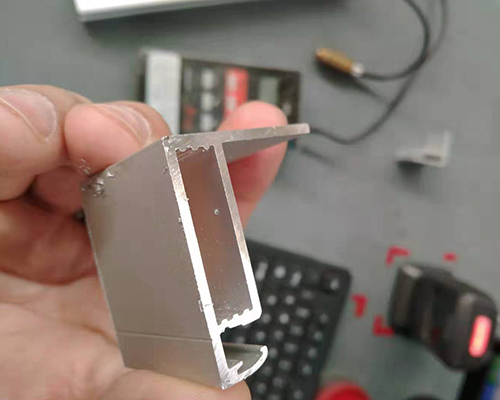

Most solar panels are made of aluminum alloy with irregular cross section. They have slots for easy installation of panels. The surface is anodized in silvery white color with a matte effect, while some are in black. The shape of the solar frame is extruded by the aluminum rod through a die, and the surface effect is obtained by sandblasting and anodizing.

Selection of Raw Materials

The selection of raw materials is very strict, the content of each element must meet the following standards: Si 0.38-0.42%, Mg 0.53-0.57, Fe<0.18%, see Chemical Composition is the Determinant of Aluminium Profile Performances

Importance of the Die

The extrusion die also needs to be polished carefully, especially on the decorative surface of the aluminum frame, to avoid black lines and welding lines. During the extrusion process, the temperature and extrusion speed should be strictly controlled. Especially after extrusion and quenching, the artificial aging time is controlled well, which largely determines whether the hardness of aluminum frame material reaches the standard. Generally, the hardness of aluminum profiles should be over 8HW, and that of the solar frame should be 12HW.

Sand Blasting

The aluminum frame after artificial aging should be sandblasted, and the grit of carborundum should be uniform. Abrasions should also be avoided during sandblasting.

Anodizing

The surface of the aluminum profile after sandblasting formed a matte effect, and then transferred to the workshop for surface anodizing treatment, black frame material to add a step coloring treatment. Anodizing time should also be specially controlled to increase the thickness of the anodizing layer. The layer’s thickness of ordinary aluminum profiles is about 10μ, while that of solar frame profile should be 15μ or more. Anodized materials also need to be coated to protect the surface of the material from abrasion during processing.

How to Improve the Surface quality of Solar Aluminum Frame

1. Select the appropriate extrusion parameters

According to the extrusion coefficient, profile section, die, equipment, etc., choose the best extrusion temperature, casting rod heating temperature, die temperature and extrusion speed, and constantly adjust these parameters in the production process.

2. Improve the quality of cast rod

In the process of casting rod, the technology of grain refinement was adopted and effective measures were taken to reduce the defects such as slag inclusion, porosity, and coarse grain. In addition, to strengthen the analysis of the low-strength microstructure of the cast bar, quality control, reduce the defective cast rod put into use.

If you need this kind of products or want to know our existing specifications and models, please contact us directly.