Project Description

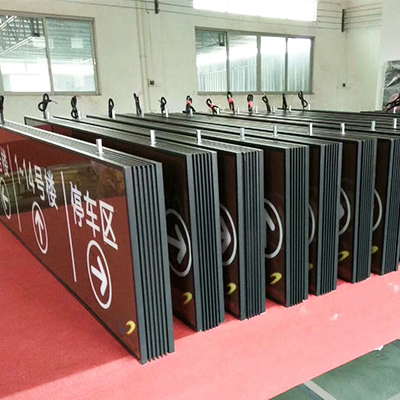

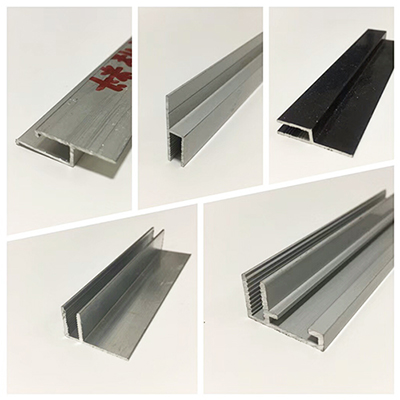

Aluminium Extruded Frame for Light-Box

The aluminium profile is widely used in advertisement lightbox with beautiful and generous characteristics. The folding box can be folded into a specific shape with a special bending machine. It can be folded into a square, circular, oval, etc. It is widely used in the production of plastic lamp box.

The classification of aluminium profile of lightbox:

- Aluminium profile with corner lightbox

- Bended lightbox aluminium profile

- Ultra-thin lightbox aluminium profile (General Wall Thickness is 0.8 mm)

- Electronic bar screen aluminum profile

- CCFL, EEFL and LED light box aluminum profiles.

The open-style ultra-thin light box aluminium profile is used to make all kinds of super thin light boxes, which have beautiful appearance and easy to replace the image. And widely used in commercial centre interior decoration, chain store, company sign, commercial center, supermarket, airport, station, subway, bank, large exhibition project.

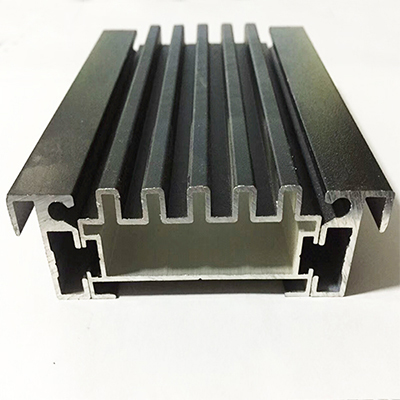

LED Aluminium Extruded Frame

LED panel lamp is high-end interior lighting lamps and lanterns, the outside borders are composed of aluminium alloy profile by anodic oxidation, the light source for LED, the design of lamps and lanterns is beautifully concise, atmospheric luxury, both good lighting effect and give people aesthetic feeling.

LED panel lamp design is unique, light after high light transmittance of the guide plate to form a uniform plane light effect, the intensity of illumination uniformity is good, the light is soft and comfortable yet bright, can effectively alleviate eye fatigue. LED panel lights can also prevent radiation from stimulating the skin of pregnant women, the elderly and children.

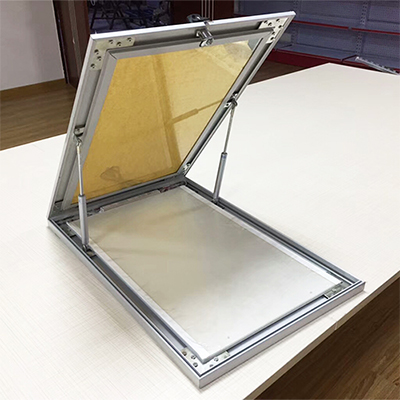

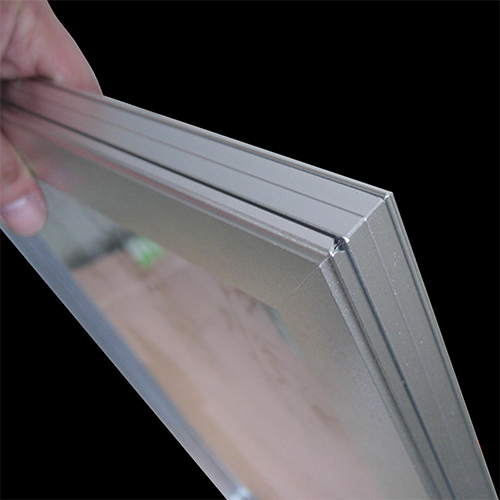

Aluminium Picture Frame – Aluminium Display Border

These aluminium extruded frame cover Aluminium Poster Border, Aluminium Roll Up Banner, Aluminum Glasses frames, Aluminium Banner Stand, etc.

The main reasons for choosing aluminium alloy as the frame and border:

- The plasticity of aluminium alloy – it can be extruded into various shapes.

- lightweight but high strength and tension.

- Corrosion resistance and Low maintenance.

- Decorative – Rich and varied surface colors are very decorative.

- Cheap and Recyclable.

Extruded Aluminium Rim for Bicycle

Today, bicycles have become the simplest, most practical and most used means of the vehicle in the world. Sharing Bikes, in particular, is becoming more and more popular. Now the fabric of the bicycle is mainly made of aluminium alloy, magnesium alloy, titanium alloy and carbon fiber. The bicycle frame greatly reduces the weight of the bicycle. The multi-speed transmission mechanism makes the bicycle faster and faster.

While the performance of bicycle has greatly improved, the stability of bicycle operation has been paid more and more attention by consumers, especially the mountain bike. Bicycle wheel or rim is an important part that keeps the bike running smoothly. Because that aluminium alloy is cheaper than the magnesium alloy, titanium alloy, and carbon fiber material, and possesses the advantages of lightweight, not rust, therefore, the most current used is aluminium alloy rim.

Currently, the common aluminium rim contains Single-wall and Double-Wall aluminium rim. Because the spoke & nipple directly touches the inner tire in Single-wall aluminium rim, it’s easy to wear out inner tire. But double-wall aluminium rim is to overcome this shortcoming, at the same time, strengthen the intensity. Therefore double-wall aluminium rim has more advantages.

The material of aluminium bicycle rim is aluminium alloy 6061-T6 (Click here to learn more about Aluminium Alloy 6061); alloy 6061 belongs to Al-Mg-Si series, moderate intensity, and has good plasticity and excellent corrosion resistance. In particular, there is no stress corrosion cracking tendency, it has good welding property, corrosion resistance and cold processing. The surface can be anodized oxidation and applied enamel to lacquer. Because alloy 6061 contains a small amount of Cu, the strength and quenching sensitivity is higher than alloy 6063.