Project Description

The seamless aluminum tube is made of pure aluminum or aluminum alloy by extrusion processing along its longitudinal length of the hollow aluminum tube without weld. The seamless tube will ideally be a solid metal tube with each end connected to another tube without having any welding joint.

Seamless Aluminum Tube Classification:

According to the processing method is divided into extrusion seamless aluminum tube, cold drawn precision seamless aluminum tube, rolling seamless aluminum tube. Among them, the cold drawing precision of seamless aluminum tube with high precision, good surface quality.

The Main Process of Seamless Aluminum Tube:

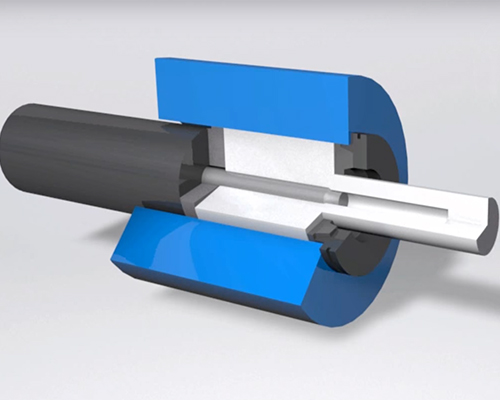

Seamless aluminum tubes are produced by piercing extrusion, while conventional aluminum tubes are usually extruded by a combined die. Aluminum Alloy seamless tube production principle and process production using the short rod, high temperature, slow speed extrusion process, especially to control the “three temperature”, aluminum rod extrusion cylinder, and die to keep clean, aging time and temperature are adjusted according to the thickness and diameter of the wall.

The Difference Between a Seamless Tube and a Slit Tube:

A seamless tube is a tube that does not have any welding seam. A seamless tube may also be known as a seamless pipe. It differs from the main slit tube in that:

Aluminum ingot processing method:

- Indirect extrusion (seamless tube) surface turning, no scale involved.

- Direct extrusion (slit tube) of the skin without turning, the product may be involved in the oxide layer.

Status of aluminum ingot and container:

- Seamless pipe flow, frictionless;Uniform flow of metal;

- There is relative friction in the slit pipe. Uneven metal flow; The product contains coarse crystals.

Product appearance:

- The inner and outer walls of seamless tube are smooth and clean.No burning or cracking on the surface;

- The appearance of slit tube is generally smooth.

Mechanical properties:

- Seamless tube product head and tail metal flow uniformity; High dimensional accuracy; Good fatigue resistance; Consistent mechanical properties;No lamellar tissue.

- Metal flow from end to end of products with slit pipes is not uniform; Mechanical properties inconsistent; Lamellar tissue is easy to appear.

Product category:

- Seamless tube is especially suitable for extrusion of alloy bars and tubes with super hardness (such as alloy 2014, alloy 5056, alloy 7075 series).

- Slit tubes are suitable for extrusion of general hardness of alloy products of general added value.

Economy:

- Seamless tube relatively high price, suitable for manufacturing high-precision products.

- Slit tubes are relatively inexpensive and suitable for general purpose products.

Main Features and Application of Alloy 7075 Seamless Tube:

Features:

- High Strength Heat treatable alloy.

- Good mechanical properties.

- Good usability.

- Easy to process, good wear resistance.

- Good corrosion resistance and oxidation resistance.

Application:

The aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, gaoerfu ball head, shoe mold, paper mold, foam molding mold, wax mold, template, fixture, mechanical equipment, mold processing.