Project Description

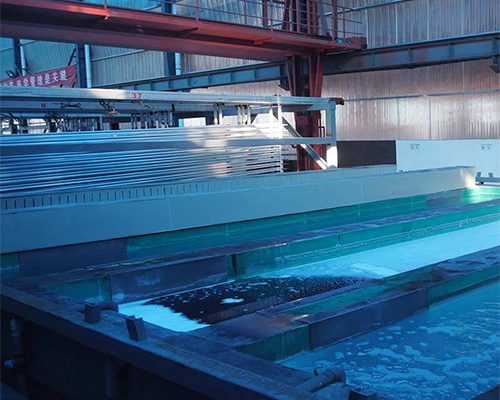

The temperature of anodic oxidation solution is the dominant process parameter affecting the properties of the oxide film. When the temperature increases the viscosity of the solution decreases, the current density increases (while the voltage is constant). When the voltage decreases and the current are constant, the energy consumption can be reduced and the production efficiency can be improved.

When the temperature of the anodic oxidation solution is more than 24 ℃, the dissolution rate of the film layer is increased, which caused the production rate of film, the hardness of film and the thickness of the film layer reduce, the capacity of wear resistance and corrosion resistance down, and the oxide film becomes loose. So at this point do everything possible to reduce the temperature of the solution. However when the temperature of the solution is too low, let’s say it below 12℃, the good news is that the thickness of oxide film can be increased, and the capacity of wear resistance is also better; But the oxide film’s brittleness increases, the porosity is small and the dyeing is difficult. Therefore, while anodizing aluminium alloy profiles, the solution temperature must be strictly controlled to prevent the solution from being too cold.

Anodic oxidation is the exothermic reaction; the formation of the oxide film is accompanied by the production of joules so that the temperature of the solution rises rapidly. When anodizing, it is necessary to take corresponding measures to control the temperature of the solution in the normal process specification (between 12℃ to 24 ℃), so as to ensure the formation of the oxide film can continue with quality. When the temperature is too low to meet the requirement of dyeing, the general parts can be firstly processed, then waiting for the temperature increased, the dyeing profiles will be processed.

How to control the process? It’s a matter of experience.