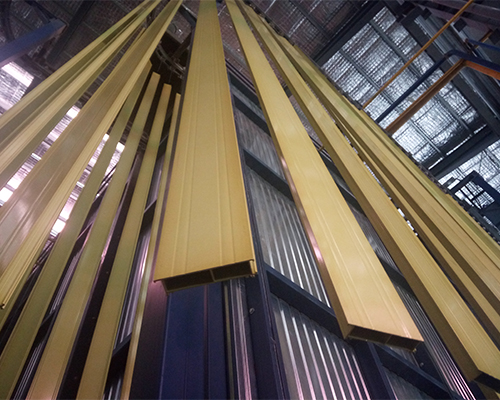

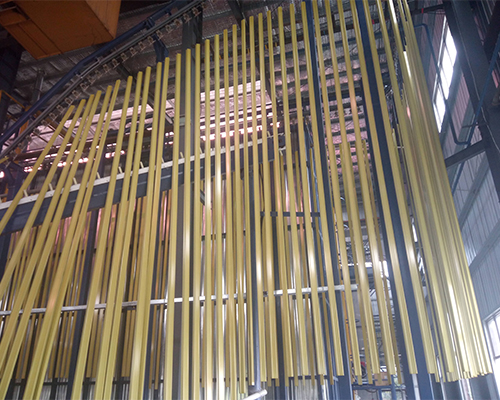

Project Description

Before, We discussed that several matters in process of aluminium profile powder coating, and got a general idea of powder coating. Today we will analyze some of the problems that may arise during the spraying process and propose solutions. This is very helpful to improve the product quality.

The causes and solutions of the powder fluidization in the spraying process

- the compressed air pressure is not enough to check the compressed air supply, clean air filtration equipment, and increase the pressure properly.

- the microporous plate is blocked, which can be used to check whether the microporous plate is blocked by superfine powder or the oil and impurities in the compressed air.

- the powder will be stored in a powder keg for a long time, but try to increase the pressure for a long time to sulfurate the powder, take out the moisture, and use a clean utensil to stir it when necessary.

- the powder can be used to screen the powder loosely.

- there is too much powder in the vulcanized bed, which can reduce the amount of powder in the bed. The amount of powder can be added to two-thirds of the volume of the vulcanized bed.

Reasons and solutions for the hardness of the surface after curing of powder coating

- curing insufficiency can raise the baking temperature to meet the process requirements or extend the drying time to meet the process requirements.

- curing excessive, coating embrittlement also reduces hardness, can reduce baking temperature properly and shorten the baking time.

- the heating rate is too slow, and during the slow melting and flow, some of the fluiping auxiliaries are transferred to the floating surface, which can increase the heating rate to the coating surface.

- the quality of the powder itself may inform the powder supplier to improve the formula.

Causes and solutions of color discoloration after curing of powder coatings

1) the baking time is too long to shorten the baking time.

2) excessive baking temperature can reduce the baking temperature.

3) uneven coating thickness.

- the position or direction of the spray gun is incorrect, which is affected by the Faraday effect and should be checked and reset.

- the vibrator of the automatic gun is not matched with the production line speed. It should adjust the production line speed or adjust the air gun vibrator stroke.

- the air flow in the powder chamber influences the spray range of powder and should contact the equipment supplier.

- spray gun powder is not uniform, the powder and spray gun system should be checked to ensure the powder vulcanization and spray uniformity;

- high voltage instability should check the output voltage.

4) the air in the oven is not clean and should check the air heating system and exhaust air.

5) if there is a problem with the powder formula, contact the powder supplier.