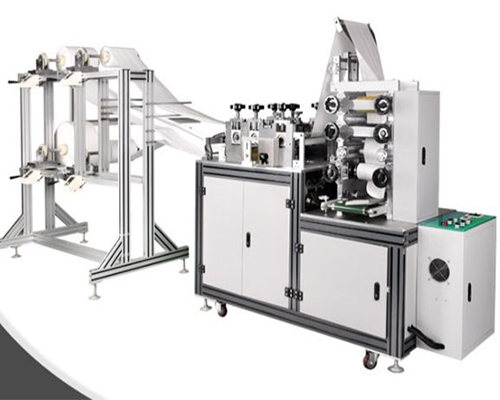

Project Description

As a result of the global epidemic, the natural environment is deteriorating. People’s awareness of protection is increasing. Face mask machine demand is also expanding. Many manufacturers have found the mask machine industry profits, and have expanded production. For the mask machine, everyone may be relatively unfamiliar. The framework of making mask machine equipment is the industrial aluminum profile. And it’s generally aluminum profile S8-4080.

Why Choose 4080 Aluminum Profile for Mask Machine Equipment?

— Strong Bearing Capacity. 4080 Aluminum Profiles are generally divided into light and heavy profiles. They are the only difference in wall thickness and bearing capacity. But for the general mask machine, 4080 light can meet the demand.

— 4080 Aluminum Extrusion is treated by anodizing. It has the functions of anti-corrosion, sterile clean, and easy to process and handle. The equipment assembled with 4080 profiles is stable and durable. It is also convenient to expand and upgrade the equipment in the later stage.

What is the Connection Method of the Mask Machine Equipment?

The whole framework adopts the assembly line aluminum 4080 and 4040 aluminum profiles, which are connected with the inner hexagon bolts. Mobile casters are installed at the bottom for flexible movement.

A part of the aluminum frame is used to hang the raw material used to make masks. The part is an aluminum shaped chassis working table, which is used for mask making equipment (welding equipment, bearing, etc.). The framework can be automated that can increase production.

What are the advantages and characteristics of a frame made of 4080 aluminum profiles?

First of all, whether it is a masking machine assembly line or protective clothing production equipment assembly line, are required to customize. Each type of equipment and specifications are different. Custom-made frames made of industrial aluminum profiles have more advantages than those made of materials such as stainless steel. It doesn’t have to be welded, it doesn’t have to worry about gaps and instability.

Secondly, the aluminum surface is anodized to ensure the anti-corrosion and durability of aluminum. Mask machine production works long hours. It has high requirements for equipment. Production mask environment in the dust-free workshop operation. The mechanical equipment of the mask is easy to clean.

Finally, aluminum can be processed with the size of the machine. Such as assembly line workbench, conveyor mask chain, mask machine equipment frame. Customers only need to provide design and processing drawings. HOONLY CNC machining center provides perfect after-sales service.