Project Description

Compared with traditional lights, LED (Light Emitting Diode) lamps have the advantages of long service life, energy saving, and high light efficiency. In recent years, LED lights are increasingly used in various industries, such as street lamps, industrial and mining lamps, landscape lamps, indoor lighting, etc.

However, the LED lamp also has certain disadvantages. For example, its calorific value is very high, and when the temperature rises to a certain degree, it will affect the lifespan and luminous effect. In practice, LED light conversion efficiency is about 30%. The remaining 70% will be released as heat. LED heat rise has a direct impact on luminous efficiency, main wavelength instability, low chromatic aberration. Therefore, for a good LED lights, the first to consider is the heat dissipation problem, the choice or design of a good heat sink is crucial.

To do a good job of the LED light with heat sink, we should know three ways of heat movement: Heat conduction, Heat convection, and Heat radiation. Heat conduction and convection need to use the medium to dissipate heat.

For High Power LEDs, the maximum allowable Junction Temperature is 125 °C for short time, 110 °C for a long time; and 80 °C for Low Power LEDs. (Junction Temperature: Refers to the temperature of a semiconductor junction in the main heating part of LED devices. It is the temperature value that reflects whether the LED device can bear under working conditions.)

Therefore, we usually need to consider the following aspects in Heat Sink design: Thermal conductive materials, Conductive media, Thermal energy location, Heat absorption interface, Heat flow direction, Environmental temperature and so on.

Heat Sink Optimization

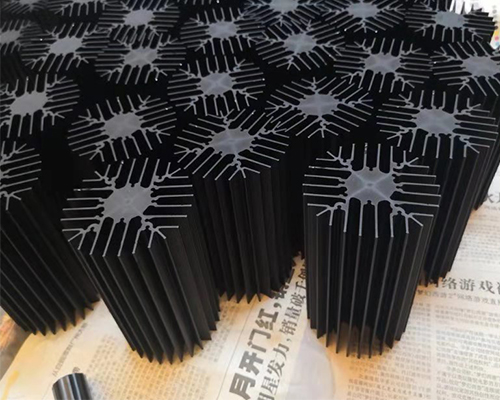

Aluminum LED Lamp Heat Sink: The light source or light source aluminum substrate close to the heat sink and fixed, use the heat sink to dissipate the heat in the surrounding space, if necessary, plus cooling fan, with a certain wind speed to enhance the cooling.

Previously, we introduced three shapes of aluminum alloy heatsink:

The teeth length and thickness, root thickness, groove width, groove number, and teeth interval of LED Heat Sink will affect the heat dissipation performance.

According to HOONLY’s years of practical experience, without affecting the physical performance of LED Heat Sink:

- The thickness of Root should be reduced as much as possible to reduce the cost of LED lights;

- The width of the groove should be reduced as much as possible with a reference value of 1 mm;

- Try to increase the number of groove and teeth.

- Teeth thickness and interval should be determined according to the actual situation. We recommend the value 2 mm for both.