Project Description

Aluminum profile is a commonly used industrial material at present. In addition to the commonly used specifications, it also involves a variety of custom aluminum extrusion. Customized products are developed according to users’ requirements, which are more specific and have a single application area. However, it is an integral part. The advantage of custom aluminum extrusion is that they are relatively dependent and can closely connect manufacturers and users. The following details are introduction of custom-made aluminium profile specific steps, for reference only.

The Steps of Custom Aluminum Extrusion:

- Detailed understanding of product parameters according to usage requirements, such as specification, size, mechanical properties, configuration, etc. (the difficulty of product specification, size and structure will directly affect the cost input of tool/die and customization);

- Based on the above information, technicians start to issue design drawings and technical parameters;

- Both parties shall confirm the drawings and seal, the purpose is confirming the implementation standards and test standards. Third-party testing can also be specified;

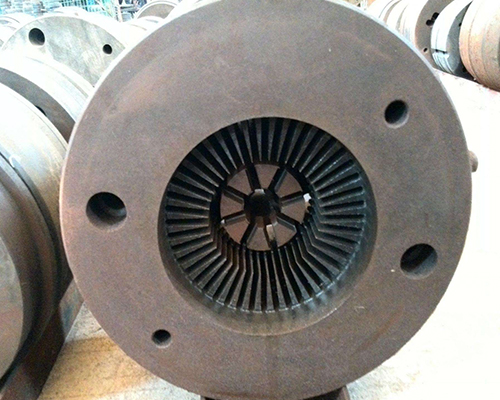

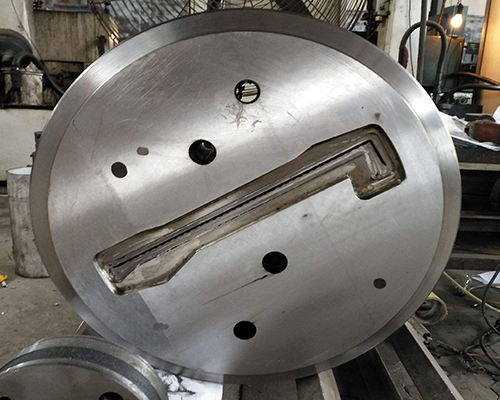

- Tooling/die making;

- According to the tool/die, the sample is extruded and sent to confirm. If the sample is correct, the mass production can be carried out.

Precision Control of Custom Aluminum Extrusion:

The requirement of precision extrusion technology for aluminum profile is very strict. In the production process, there are strict requirements on extrusion equipment, extrusion die and extrusion technology. The control range of product accuracy is ±0.04 mm.

Tool/die design accuracy and its material process, are the main factors that directly affects the quality and size procision of custom aluminum products. The selection of tool/die material must meet the requirements of high hardness, high temperature and friction resisting.

Extrusion die normal working environment temperature is at about 500 ℃. The yield strength of the die material under high temperature shall not be less than 1200N/mm2. The friction resistance under high temperature is mainly reflected in the hardness and thickness of nitrification layer. Generally, the hardness of nitride layer should be above 1150 HV and the thickness should be between 0.25 mm and 0.45 mm. The accuracy change of the die after nitrification should be controlled within 0.02 mm.

Cost Accounting of Custom Aluminum Extrusion:

Tool/die cost is calculated according to the degree of die complexity, specification and section size, and the required tonnage of the extruder. Meanwhile, the tool/die cost will be refunded after the customer has reached a certain level of usage.

Summary:

To learn more about extrusion capabilities or how to use best design practices to design the perfect aluminum extrusion profile, please contact our sales team for a copy of Engineering Guide for Aluminum Extrusions. Hoonly differentiate themselves through the precision and custom aluminum extrusion options. Please allow to assist in the die design process, and by working together to reach the best possible design at the lowest cost to you.