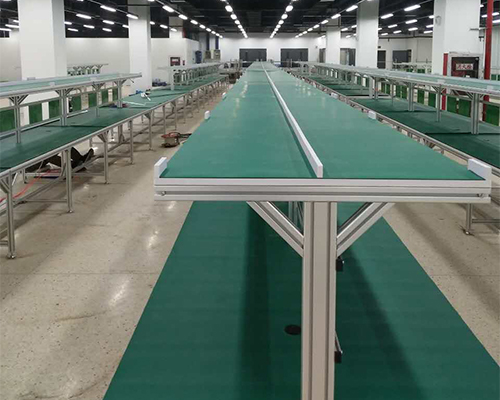

Project Description

Workbench is a necessary tool for the factory, and the workshop will be customized to start the work. Today we are going to briefly introduce the process of making the workbench.

1. Aluminum Extrusion Profile

Aluminum material often is used as the main framework when assembly workbench. Especially choose T-slot aluminium profiles that all around of the slotted standard aluminium profile. In accordance with the requirements of bearing, and the table size, you can choose and buy of 20 mm -100 mm thick aluminum extrusions. The thickness is not solid. It will have more than one cavity, the cavity design accord with mechanics principle, which can ensure its bearing capacity, and to reduce the material weight. The most commonly used is T-slot 4040 industrial aluminium profile, it is the cross-section width of 40 mm, wall thickness also can choose according to needs, a slim profile, standard profiles, and thick wall profiles. There are many types of 4040 aluminium profiles. The aluminium profile frame is extruded by extrusion machine. It is hardened by hardening and artificial time.

2. Anodic Oxidation

After extruding, the aluminium profile can form natural oxidation film. But it is not uniform, not strong corrosion resistance, and the surface is not good, and the colour is not uniform. After anodized aluminium profile forms a dense oxide film. It can effectively protect the aluminium profile from oxidation corrosion. Anodizing is the electricity process that can be used on both ends of the aluminium profile to form an artificial oxide film.

3. Sawing

According to the drawings designed by the technician, the cutting is done. The accuracy is required to be ±0.2 mm.

4. Table Frame Assembly

Assembly workbench according to the drawing, please note that assemble the part where the workbench is vertical first. This is generally used for the bolt & nut and the assembly line of the aluminium profile special corner. The connection part should be fastened with a fastening device to ensure that no accidents occur in the use of the workbench.

5. Install Whiteboard

Whiteboard is an essential part of the most assembly line equipment. It can be used to place instructions or matters needing attention. Install the aluminium extruding materials according to the requirements to be installed on the top of the workbench, a total of two, green workload whiteboard is installed in the middle.

6. Installation of Countertops

Most of the mesa workbench is composed of high-density composite board and anti-static materials, the composite board after the clean up one side of the spray a layer of glue, then anti-static rubber cover on it. At the same time, the countertop is to be carried around to wrap around, prevent workbench to appear problem in use medium mesa. The finished table and the assembled workbench frame are installed together, and a set of the simple workbench is completed.