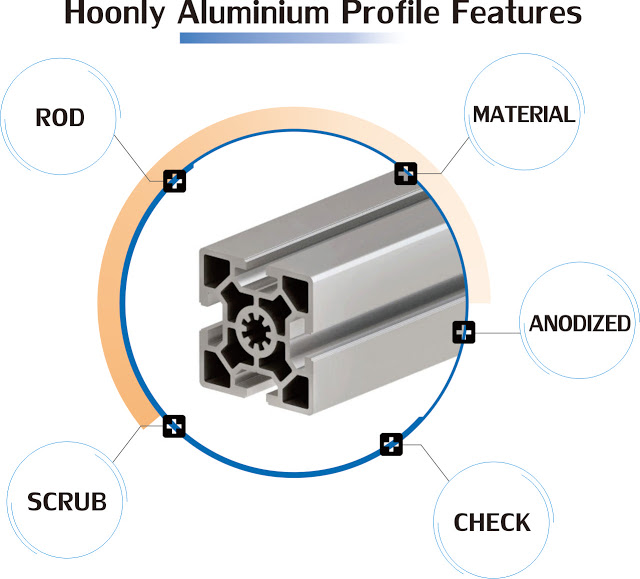

Project Description

Rod:

The production cost of aluminium rod is higher, however, the traditional casting process does not guarantee uniform distribution of aluminium alloy, which easily causes the surface blemish.

Hoonly puts homogeneous aluminium rod to use, and it will reduce die/ mold wastage during extrusion, thus improving aluminium profile’s surface finish and mechanical property.

Scrub:

Non-scrub treatment is extremely easy to cause surface blemishes.

Hoonly adopts means of frosting oxidized, beauty surface, no blemishes.

Material:

Using recycling scrap aluminium as the raw material to save costs, the produced aluminium profile is usually out of flatness and grey surface even easy to breakage due to the high content of impurities.

Hoonly’s raw material is A00 standard aluminium ingot that contents 99.99% Al.

Anodized:

To save costs and increase production speeds, reduce anodized time, which causes the thickness of oxidation film not up to standard.

The oxidation film thickness of Hoonly products is more than 30% of national standard.

Check:

Hoonly owns detection tools such as Spectroscope, end face measuring instrument, hardness testing and film thickness measurement etc, there are 12 rigorous testing procedures. Hoonly has been committed to producing high-quality aluminium profiles.