Project Description

How to prevent black trail and slag inclusion in the extrusion process of aluminium alloy 6063 & 6061?

In order to solve the problems of black trail and slag inclusion, reduce the amount of scrap and improve the yield during the extrusion process of alloy 6063 aluminium and alloy 6061 aluminium, there are three methods worth mentioning after long-term follow-up and study.

Production process control

- Blow the dust off the aluminium bar using air blower when finish cutting, so that reducing the amount of dust that is carried by aluminium bar, which takes the effect of source reduction.

- Enough discard pressure should be kept, too much will lead aluminium into the profile end and cause black trail and slag inclusion.

- The extruded speed should be controlled effectively. Especially at the end of aluminium bar, the speed should be slow down, to prevent impurities getting in with turbulent flow.

- The cylinders of aluminium extrusion machine should be cleaned every production period.

Equipment adjustment

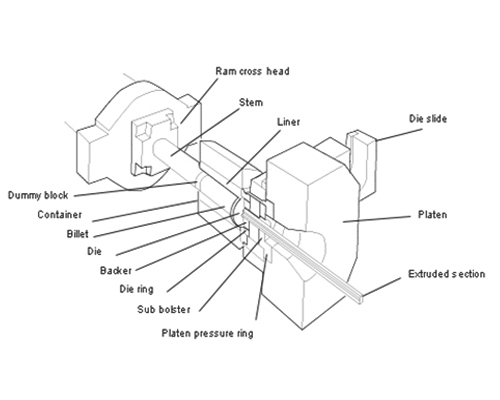

- Extrusion ram should be centered, or it will wear the billet and then expand it.

- The billet will be deformation long term usage, so it needs to be taken seriously. The new billet should be cleaned up and the inner should be polished before installation.

- The die should be centered too, it is forbidden to extrude when the die no center alignment.

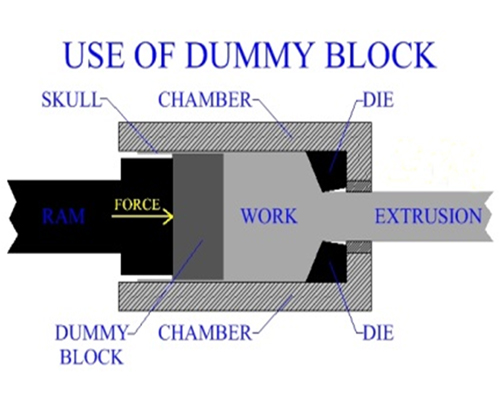

- The dummy block should be checked and renew regularly, pay special attention to changing the lipped flange dummy block.

Die design and production plan adjustment

- Refer to flat die, it’s necessary to add deflector that reduces the intake.

- The die’s divergent hollows should be covered in billet, if the hollows are large, the production should be stopped.

- When planning the production schedule, the die should match with extrusion machine tonnage according to the diameter of aluminium bar for example.