Project Description

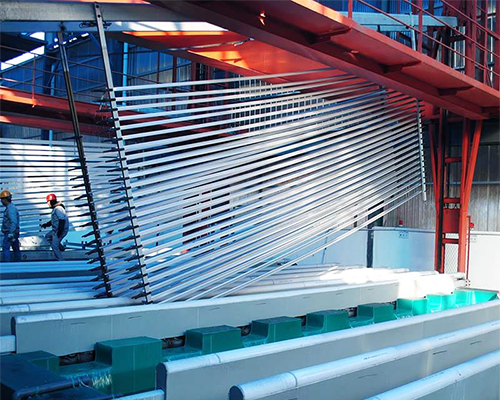

Aluminium profiles are aluminium materials with different cross-section shapes through hot melt and extrusion. The production process of aluminium profiles mainly consists of three processes: melting, extrusion and colouring (The most common surface treatment includes oxidation, electrophoretic coating, fluorine spraying, powder coating, etc.).

The aluminium profiles are divided into:

- Industrial aluminium profile: mainly used for aeroplanes, trains, industrial radiators, automobiles, electrical appliances, etc.

- Aluminium alloy profile for building: mainly used for building doors and Windows, curtain walls, indoor and outdoor decoration and architectural structure.

Surface treatments are divided into:

- Anodized aluminium: the surface of the profile is oxidized by anodic oxidation, electrolytic colouring or organic colouring.

- Electrophoresis coating aluminium: the surface of the profile is combined with anodic oxidation and electrophoresis.

- Powder spraying aluminium: the surface of the profile is coated with thermosetting organic polymer powder.

- Fluorocarbon paint spraying aluminium: the profile surface is coated with polyvinylidene fluoride paint. At present, the commonly used heat insulation profile is a kind of aluminium profile which adopts a strip or pouring compound.

Key Indicators

1. Appearance quality: the surface of anodized profile does not allow for the defects such as electric burn and peeling of oxide film; Electrophoresis, powder, fluorine carbon profile after the paint film should be uniform, clean, smooth, there is no wrinkle, crack, bubble, flow mark, inclusion and peeling paint film effects such as the use of defects, but within the scope of the profile end 80 mm allows local without membrane. The appearance quality of the aluminium alloy building profile affects the architectural decoration effect, so the surface of the factory profile must be coated to avoid surface scratch, collision and corrosion in the process of transportation and stacking. In the market, some aluminium alloy profiles have similar patterns of water striation and mildew, which reflect the defects of the production process.

2. Wall thickness: the wall thickness of the profile is one of the main factors affecting the strength of the workpiece. The main profile is the stressed part of the project. For example, the minimum nominal wall thickness of the outer window main profile shall not be less than 1.4mm.

3. Film thickness: extruded aluminium alloy profiles, whose surface corrosion resistance is not strong, the surface treatment should be carried out to increase the corrosion resistance, wear resistance and appearance aesthetics of aluminium. The film thickness of anodized aluminum material is divided into AA10, AA15, AA20, AA25, and the thickness of the electrophoretic coating aluminum film is divided into A.B.S, powder spraying aluminum decorative coating on the surface of the minimum local thickness of 40 um or higher, fluorocarbon spraying aluminum decorative paint on the surface of the layer thickness for coating of different kinds have different requirements, the second with the average film thickness acuity 30 um to 40 um, three with the average film thickness acuity, 4 with an average of 65 um film thickness acuity.

4. Chemical composition and mechanical properties: the technical parameters of chemical composition and mechanical properties of aluminium alloy profiles are different, and the customer should check them one by one according to the standard (Contract Terms).

5. Colour difference: there are differences in colour brands and supply states. It is suggested that the influence of colour difference on architectural structure should be taken into consideration when the alloy plate number and supply status are selected.

6. Anti-salt spray corrosion, abrasion, waiting and mortar, etc.: this is an important technical parameter of aluminium alloy profile, which reflects the properties of aluminium alloy profiles and influences the use.

Characteristics and properties of various aluminium profile surface treatment processes:

Frosted fabric profile: frosted surface aluminum avoids the polished aluminum alloy profiles in architectural decoration exists in certain environment, conditions will form the interference of light, it’s like brocade and soft surface, is very popular with the market, but the existing grinding material must overcome sand uneven surface, and can see the shortage of the die lines.

More tonal and surface treatment of aluminum: currently, the monotony of silvery white and tan already cannot satisfy architects tile, exterior wall latex with exterior wall decoration is very good, a new type of stainless steel color, champagne color series, gold, titanium gold, red, wine red, purplish red, black, purple combined with such as colored glass can make adornment effect is the icing on the cake. These profiles must be chemically or mechanically polished and then oxidized to produce a good effect.

Electrophoretic coating aluminium profile: the surface gloss of electrophoretic coating is soft, it can resist the penetration of cement and slurry acid rain, 90% of the aluminium profiles are electrophoretic paint.

Powder electrostatic spraying aluminium profile: powder electrostatic spraying profile is characterized by excellent corrosion resistance and acid and alkali salt fog.

Plasma-enhanced electrochemical surface ceramic profile: this kind of profile is the most advanced processing technology in the world. The products are of good quality but high cost. It has more than 20 kinds of tonal, its biggest characteristic is according to need to be like a printing cloth to be lubricious, the surface of shape material is profusion, adornment effect is very good.