Project Description

What is Extruded Aluminium Motor Body?

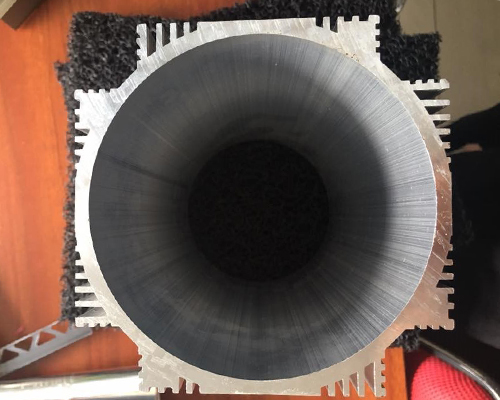

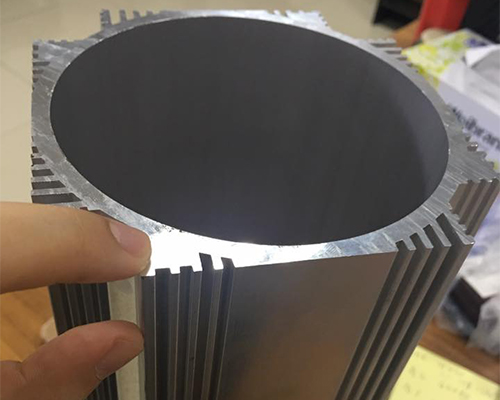

Aluminium Motor Body, also called aluminium motor enclosure, is a kind of aluminium shell with the extrusion forming, which can be used to place instrument measuring tools and other applications. Generally including the shell, panel, lining plate, support and other components. The aluminium motor housing is mainly used to protect the internal parts.

Why Extruded Aluminium Motor Body?

The research and development of extruded aluminium shell have successfully replaced the aluminium casting shell. Because it solves the problems of porosity, sand hole and other defects which caused by the poor material density of cast aluminium. At the same time, the matters of surface roughness and low corrosion resistance of cast aluminium are settled.

Modern precision processing equipment (CNC machines) improves the efficiency of the deep processing of aluminium motor housing.

At the same time, the problem of surface roughness and corrosion resistance of cast aluminium alloy electromechanical shell is solved. The error of end cover concentricity (Hoonly controllable at Inner hole concentricity is less than 0.07 mm) is extremely small. The electric machine motor runs more smoothly and quietly.

Advantages of Extruded Aluminium Motor Body

Extruded Aluminium housing is superior to other materials in heat dissipation. The motor will generate the amount of heat in the working process, while the aluminium motor shell will keep the temperature within a certain range when working for several hours. We know that aluminium has a high thermal solubility. Based on such characteristics, the manufacturers of speed reducer motors in the market use aluminium shell.

Aluminium motor body is light in weight. This is determined by the metal properties of aluminium alloy. On the basis of such characteristics, aluminium motor casing is widely used in household appliances, such as soybean milk machine, juicer, liquidizer and so on.

Aluminium alloy has good plasticity. Especially alloy 6063, has excellent elasticity. Various shapes of aluminium motor body are available. It greatly enriches the end customers’ choice of motor appearance.

The application range of aluminium motor housing is wide. It is widely used in instruments, electronics, communications, automation, sensors, smart CARDS, industrial control, precision machinery and other industries. When applied to decoration or special occasions, the surface of aluminium motor housing needs to be anodized and coated to obtain the corresponding colour and surface tissue.

Summary

There are many manufacturing processes of aluminium motor body. It is involved in precision machinery, fine chemical industry, micro-machining, magnetic material processing, winding manufacturing, insulation treatment and other technologies. In order to ensure the quality of the products, a series of precision testing instruments are needed too. In short, the aluminium motor housing industry is a labour-intensive and technology-intensive high-tech industry. HOONLY adheres to the mutually beneficial marketing strategy and wholeheartedly welcomes new and old customers to inquire and negotiate business.