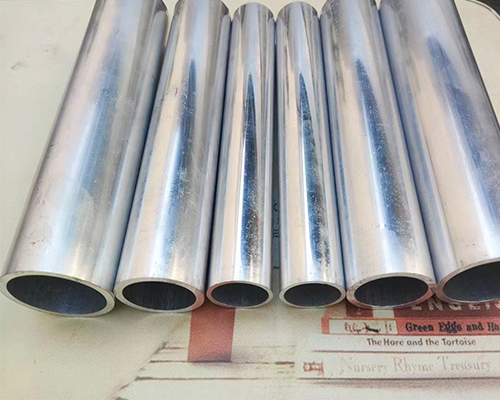

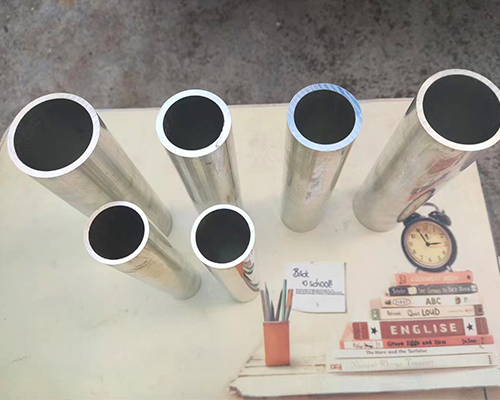

Aluminum Extrusion Tube

Hoonly provides a variety of specifications for aluminum extruded tubes, whether it’s structural tubes or seamless tubes. At the same time, customized aluminum tubes are available too. For more structural extruded profiles please visit the customized aluminum profiles.

The hot extrusion method gives extruded tube its final dimensions and allows for seamless or non-seamless construction. Although seamless and structural pipe and tube cannot be distinguished visually from one another, they are distinct, and your application will determine which is best.

What’s the seamless aluminum tube?

By using a press machine, both structural and seamless tubes are extruded. This implies that similar to the extrusion technique used to create other structural profiles, the aluminum billet is forced through a hole in a die that has been formed to create the two-dimensional cross-section you require.

Either the bridge dies method or the porthole method is used to create the structural tubes. At high temperatures (About 400 ℃ – 500 ℃), a solid aluminum billet is driven through the die with great force. While going through the extrusion die, the tube separates throughout the process and is put back together by an intrinsic welding process. If the tube is anodized or other processing, the seam is just barely visible enough to be seen with the unaided eye.

Applications for Seamless and Structural Aluminum Extrusion

Internal pressure applications need the use of seamless extruded tubes. Examples include hydraulic cylinders, pipes, and fittings. They are also employed when the extrusion will be deformed significantly. Bending electrical conduit or bus bars is a good illustration of this.

Another type of application involves high loads, which will distort the tube or extrusion if it is not strong enough. Aircraft seat frames, baseball bats, and driveshafts are examples of this type. When looks are crucial, you may also choose the seamless. This is especially true if the extrusion will be anodized, as the seam will be highlighted.

Structural tubing is suitable for all applications that do not require strong forces. Examples include railings and window frames, as well as wall framing and other architectural and aesthetic applications. More industrial examples include enclosure frames, material handling carts, and machine guards. Structural tubing is also useful in many trailer and RV applications.

How to Pick a Material for the Seamless Extruded Aluminum Tube

Aluminum alloy material standards come in a variety of forms, including alloys 2024, 6061, 7075, and others. The best option will depend on how the seamless tube will be utilized, including its intended usage, whether welding is required, and other factors. It should be emphasized that the viability of mass production also entails consideration of the outer diameter and wall thickness of seamless aluminum tubes.

If you are interested in this or have any questions, please remember to contact our technical staff for related questions. And if you are unsure which direction to go in, we’ll be happy to discuss your application with you.