Hoonly Aluminium Extrusion Profile FAQ collects many common problems in product production and sales services. What more, we also detailed Hoonly’s solutions in these problems. Whether in product introduction recommendation service or in technical guidance. You can experience HOONLY’s professionalism and service comprehensiveness and sustainability.

Industrial aluminium profile with simple and easy assembly is widely used in equipment rack/crate, protective fence, robot fence, workshop partition, production line framework, shelves, exhibition display rack etc. Please visit Application to see visual case pictures.

Three Key Features of Hoonly Industrial T-slot Aluminium Profile systems:

- Building blocks with standard aluminium profiles, fasteners, and accessories, connect without machining the profile and it’s very easy to cut to length and assembly.

- Cost optimization. Low-cost standard connector and profile, no-drill connector for processing cost, no design costs, but universal connector for versatile strength.

- Fixing slots on one side, two sides, three sides and all sides and flexible connectors & accessories. From the simplest of framework or mechanisms to high precision machine building with X, Y and Z axes, a wide range of automation products are available.

They are compared to the properties of tensile strength, fatigue strength, resistance to oxidation, manufacturing cost, density and elastic modulus:

1. Tensile Strength

Aluminium Alloy’s tensile strength is 230 Mpa, Magnesium Alloy is 220 Mpa. The same volume of magnesium alloy material is not as strong as aluminum alloy.

2. Fatigue Strength

In 5×108 cyc, Aluminium Alloy’s fatigue strength index is 80 Mpa, Magnesium Alloy is 60 Mpa.

3. Resistance to Oxidation

The oxidation resistance of aluminum alloy is higher than that of magnesium alloy.

4. Manufacturing Cost

Because magnesium alloy is active metal, manufacturing equipment and environment have higher requirements, resulting in high manufacturing cost.

The melting point of the magnesium alloy is lower than that of aluminum alloy. The tensile strength of magnesium alloy castings is similar to that of aluminum alloy castings, which can reach up to 250 Mpa and up to 600 Mpa. Yield strength, elongation and aluminum alloy are not very different.

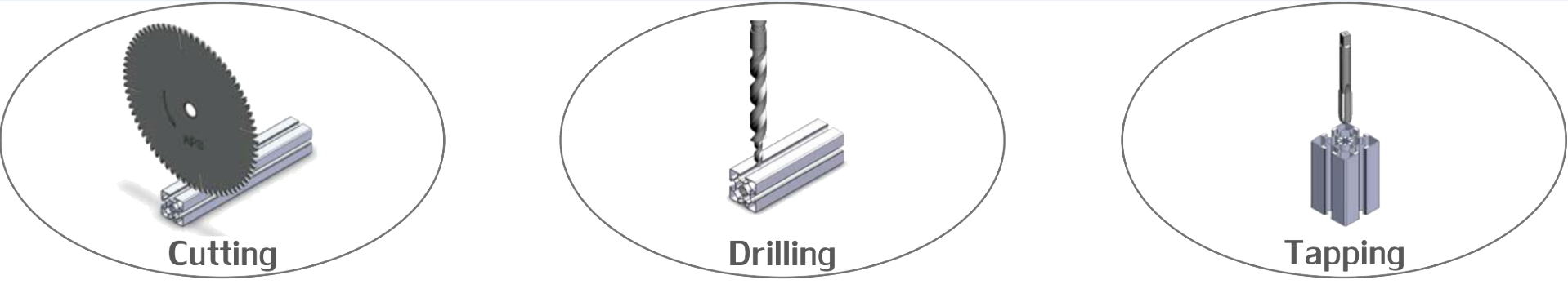

Powder coating and sandblasting belong to surface treatment, equivalent of anodizing. (Different surface treatment, different price). However, like cutting, drilling and tapping, it belongs to basis free service.

1. Hoonly is a full-service provider. Our team has the design, engineering and fabrication experience to support all of your needs, such as Kits, Bulk Material, Custom End Machining Options, and Custom Extrusions.

2. The demands of today’s business require flexible, reliable service. Service is our primary strength:

# On-time delivery of the highest quality products and solutions in the industry.

# Unparalleled service and ongoing technical support.

# Our personal guarantee that you will have what you need, when you need it and how you need it.

Complete specification and wide application

- The largest aluminium production and processing base in Central China.

- Fully equipped to achieve aluminium alloy casting, extrusion, surface treatment, and CNC further processing.

- Aluminium alloy: 5052, 6063, 6060, 6005, 6061, 6082, 7003, 7025, 7075, involved in the fields of construction, transport, machinery, chemicals, electrical, ships, and aerospace.

Opening die customization to satisfy your individual needs

- 15 years’ attentiveness and senior engineer team.

- The max section Φ700 mm, max length 30 m, anodizing length 14 m and film thickness 16 μm.

- Ensuring your exclusive use

15 years’ experience let you experience truly the joy of “Customer is God”

- Set up R&D center with University and GRINM.

- One of the suppliers of Siemens, Emerson, and Schneider etc.

The excellent modern testing center to ensure your products quality

- High precision of section projector and micron precision.

- Modern homogeneous furnace to ensure raw materials is of good quality.

- The spectrometer imported from German to make materials detection much more accurate.

Short delivery time and variety shipping mode let you worry-free

- DHL, TNT, FedEx, international express DHL, UPS, TNT, and FedEx are your options.

- Delivery time 1-3 days, extrusion and accessory are packaged separately to avoid crashing and abrasion during transport.

- As you required OEM/ODM.

Hoonly’s Basic Service covered Cutting, Drilling, and Tapping. All of these processes will be based on your request and will be free.

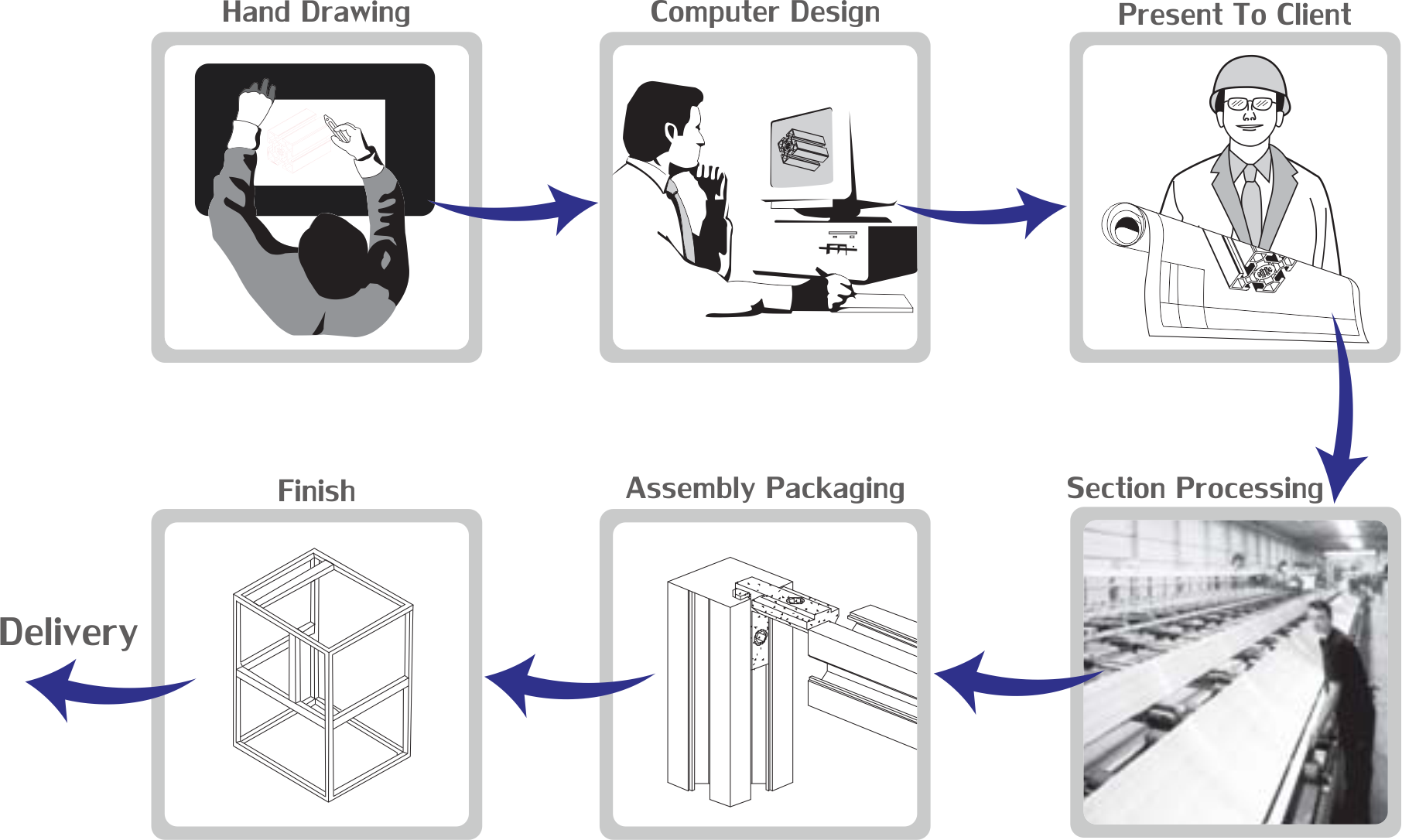

You Name it, we’ll frame it. (6 steps take you from concept to completion)

- Imagine it and hand draw it

You provide the project concept in a rough sketch - Computer Design

We will make application recommendations to provide the smartest design solution via CAD. - Present the designs

Our design engineers will help you develop the project and provide the structure layout, load calculations and a cost analysis for your confirmation. - Processing

After your confirmation and signature, usually, we will provide you the processing services for free. - Trial assembly and packaging

We trial assembly the frame and test so as to fit all force requirements before packaging. - Deliver it

We will ship it as quickly as possible.

Industrial Aluminium Profile, or Aluminium Profile System, other aliases as Industrial Aluminium Extrusion and Industrial Profiles Extrusion, which is alloy material composed mainly of aluminium. The aluminium rods are hot-melt and extruded to obtain different cross-sectional shapes. However, an added different alloy composition determines the difference between mechanical capacity and application fields of the extruded aluminium profiles.

Sandblasting is one of the surface treatment of aluminum profile

Sandblasting is to use compressed air as the power to form a high-speed jet beam, spraying the abrasive (steel sand, brown corundum, glass beads, emery, etc.) to the surface of the workpiece to be processed at high speed.

Due to the impact and cutting action of sand, the workpiece surface has a certain degree of cleanliness and different roughness.

Benefits of sandblasting aluminum

The mechanical properties of the aluminum profile surface were improved after sandblasting. It improves the fatigue resistance of aluminum profile, increases the adhesion between it and the coating, prolongs the durability of the coating, and also beneficial to the flow of paint and decoration.

SMM is an acronym for Shanghai Metals Market, and LME is an acronym for London Metals Exchange.

SMM (Click to SMM) founded in 1999 as a Chinese metals market research company, Shanghai Metals Market have been publishing the daily assessment spot prices (SMM Price) for over 100 base metals, precious metals, minor metals, recycled metals, metal powders, compounds, semis, alloys, and rare earths for over 10 years. SMM’s Shanghai Nonferrous Metals Price Index (SMMI) accurately tracks the overall situation in China’s nonferrous metals market.

LME (Click to LME) is the futures exchange with the world’s largest market in options and futures contracts on base and other metals, By definition it is a major London trading facility formed in 1877 that currently trades futures and option contracts for six major metals: aluminum, copper, lead, nickel, tin, and zinc.

It is important to large Aluminum users for watching trends in market pricing and potentially locking up futures contracts to secure firm pricing.

In the distribution market, aluminium extrusion pricing is based on money-of-the-day SMM average. To see these trends, please follow us Twitter daily update here.

Hoonly Modular T-slot aluminium profile system has applied to machine building, aluminium framework, automation industrial, material handling, belt conveyor system and machine safety guarding and enclosures. Modular aluminium structures offer high flexibility and functionality combined with visual appeal and cleanliness of anodized surface (Both silver and black colors are optional).

T-slot aluminium profiles offer several benefits

The shape of the profile creates modularity, meaning it is easily assembled and reassembled to conform to evolving needs.

The T-slot also provides the ability to add connections and join profiles to captive ends. This allows you to change your design without having to start from scratch and also enables easy expansion and retraction of your build for modifications down the road.

The T-slot profile concept is designed to allow movement while staying secure within the T-slot.

Moving on from the T-slot concept, let’s consider the benefits of aluminum. There are several advantages to T-slot aluminum profiles. Some of the biggest are:

- Strong

- Lightweight

- High strength-to-weight ratio

- Resilient

- Modularity

- Easily machined

-

- Understand the product parameters in detail according to the usage requirements. Such as specification, size, mechanical property, and morphological structure (product specification, size, and structure difficulty will directly affect the cost input of customization);

- According to the above understanding, technicians start to issue design drawings, as well as technical parameters;

- Both parties confirm the drawing and seal (Take this as the standard that examines profile dimension);

- Development of die (The dies are an important part of aluminum profile production, which determines the structural shape of the profile), detection of tool precision (The dies design precision control scope ±0.02 mm);

- According to the developed die, the sample is extruded and confirmed. After approval of the sample, the mass production can be carried out.

You can learn more Custom Aluminum Extrusion Process

All of the industrial aluminum profiles are spot commodity. We can deliver at any time after receiving your order. If the profiles need to be processed, usually it needs one more day. That’s to say 1-2 days we can deliver the goods.

Yes, we do. It’s similar to OEM service:

- Step 1: Send us the authorization letter or using your brand name.

- Step 2: We will design the packing version Logo as per your request.

- Step 3. Confirmation of the version charge.

- Step 4. Provide the OEM service on all your products.

Yes, Industry aluminium profile is a set of system. We do supply not only the profiles but matched accessories such as Joint/T bolt and bracket. Of course we retail the accessories even if you only need one piece.

Hoonly T-slot Aluminium Profile & Accessory

Hoonly Aluminium Extrusion Profiles & Custom-Made

Hoonly is a professional manufacturer engaged in aluminium alloy extrusion from the beginning of the establishment in 2003, with the goal to provide you with the best solution.

Product range not only covers standard T-slot aluminium profiles & accessories but involves customization that extruded profiles according to client’s drawings or sent samples.

You can get them freely via email us at Hello@hoonly.com.

Sure, the followings are Our Valuable Team Members. They have a lot of experience and you can learn about their detailed resume by LinkedIn.

Of course, our company is still in the rapid development period, and we believe that more and more talents will join our team.

Walter Liu

Olivia Turner

Chunshion Lau

Sure, please contact our marketing personnel and ask for the E-catalog via Email: hello@hoonly.com, or you could directly Preview it at the bottom of our website.

Sure, we can, the service process mainly includes 5 steps:

- Step 1: Please send us a detail drawing or physical sample.

- Step 2: Our engineer will make the mold/die design based on your drawing or sample.

- Step 3: Share your detailed quotation both mold/die and product.

- Step 4: Test our product for final confirmation.

- Step 5: Mass production after final confirmation.

Yes, firstly, our technical will share you the assembly drawing if it was a simple pass-through, but the frame or composition structure is complex such as equipment line involved in so many accessories, we will record the processing video and tell you what tools will be operated during assembling, then freely share you the video.

You can also log on our YouTube Homepage and watch the video.

Hoonly Aluminium Company founded in 2003 is one of leading and professional manufacturers integrating the research, design, production and sales of aluminium alloy construction profiles, industrial aluminium profiles and matching accessories. Focused on the industry of aluminium for 15 years and strictly enforced ISO-9001 international quality system certification, which made Hoonly Aluminium Company has become one of the largest aluminium manufacturers in the north of China.

Hoonly International Co., Ltd is a trading company in Henan, China. Founded in 2017, the company was formed by the merger of Hoonly Aluminium Company and Hoonly Trading Company, mainly engaged in processing and trading of aluminum products and building materials.

Since 2018, Hoonly involved in agricultural processing trade. And established trade cooperation with more than 20 countries and regions in the world.

Hoonly not only exports traditional building materials to other countries but also selects high-quality products to import Chinese market. As China’s economy becomes more open, it is believed that more and more goods from around the world will face Chinese consumers.

More details please visit http://hoonly.com

Thank you very much for your attention to our company growth, you can contact us by email or leave a message in the below, we will respond as soon as possible.